Kazi Md. Rashedul Islam

B.Sc-in-Textile Engineering (DUET)

Author & Founder: TextileTrainer.com

Email: Textiletrainer@gmail.com

Table of Contents

Introduction:

Reactive dyes are anionic soluble dyes. These dyes are applied by means of chemical reaction, the mechanism of which is difficult. They react with the fiber to form a covalent bond. They possess in their dye molecule, a reactive group that reacts with the hydroxyl groups of the cellulose to form a stable chemical linkage. The dyestuff thus becomes a part of the fiber substances.

Properties of reactive dyes:

- These dyestuff always produce a covalent bond towards the fiber.

- These are easily soluble in water.

- It can be applied to cellulosic and proteinaceous fibers.

- It gives a wide range of shades.

- These dyes are always used in an alkaline medium.

- Its all kinds of fastness properties are acceptable.

- It is very cheap and available.

- It can be used very simply.

- Electrolytic materials are used to take up the dyestuffs.

- Dyeing method of reactive is very easy.

Trade name of reactive dyes

| Trade name | Company name | Count |

| Cibacron | Ciba-Geigy | Switzerland |

| Cibacron pront | Ciba-Geigy | Switzwerland |

| Levafix | F. Bayer | W. Germany |

| Primazin | BASF | W. Germany |

| Navictive | I.D.I. Ltd. | W. Germany |

| Remazol | F. Hoechst | W. Germany |

| Procion M.H. | I.C.I. | U.K. |

| Procinyl | I.C.I. | U.K. |

| Procilan | I.C.I. | U.K. |

| Procion supra | I.C.I. | U.K. |

| Amaryl, X Amar | Dye-chem | India |

| Metacron | Mehta dye chem Ind. | India |

| Chemictive | Cheimcequip | India |

| Goldazol | Golden dyestuff | India |

| Drimarence | Sandoz | Switzerland |

| Mikaction | Mitsubishi | Japan |

Major reactive dye types:

Following types of reactive dyes are used in factory. They are:

- Cold brand dyes.

- Hot brand dyes.

- High exhaust dyes.

- Vinyl sulphone dyes.

- Bi-functional dyes.

In this article, we will use hot brand reactive dyes. Hot brand reactive is commonly used in factories. These dyes are suitable for medium to heavy fabric because it has good migration and penetration properties. Hot brand reactive dyes need a high temperature of about 900 C. In the case of reactive dyes, salt, and alkalis are necessary for the exhaustion and fixation of dyes into fiber. To get the best result, salt should be added to the dye by the dosing system. We should follow the instructions of dyestuffs manufacturers in case of the use of salt and alkalis.

Typical Recipe for Reactive Dye:

| Chemical | Amount (gm/l) |

| Wetting agent | 0.2-0.5 gm/l |

| Sequestering agent | 1.0-2.0 gm/l |

| Antifoaming agent | 0.5-1.0 gm/l |

| Dyes | 3% |

| Glauber salt | 40-60 gm/l |

| Soda ash | 10-15 gm/l |

| Lubricating agent | 1.0-2.0 gm/l |

| Temperature | 95±50 C |

| Time | 30-60 min |

| pH | 10.5±0.5 |

| M:L | 1:20 |

| Sample weight | 5 gm |

Recipe Calculation

- Total amount of liquor= 5×20= 100 ml

- Required wetting agent=Total amount of liquor×Recipe amount (gmL)1000×Stock solution

= 100×0.31000×1%

= 3 ml

- Required sequestering agent= Total amount of liquor×Recipe amount (gmL)1000×Stock solution

= 100×11000×2%

= 5 ml

- Required antifoaming agent= Total amount of liquor×Recipe amount (gmL)1000×Stock solution

= 100×0.51000×2%

= 2.5 ml

- Required soda ash= Total amount of liquor×Recipe amount (gmL)1000

= 100×101000

= 1 gm

- Required salt= Total amount of liquor×Recipe amount (gmL)1000

= 100×501000

= 5 gm

- Required lubricating agent= Total amount of liquor×Recipe amount (gmL)1000×Stock solution

= 100×11000×2%

= 5 ml

- Required dyes = Fabric weight × shade percentage stock solution

=5×3%1%

= 15 ml

- Required amount of additional water= {100-(3+5+2.5+5+15)}

= 69.5 ml

Dyeing Curve:

Dyeing Procedure:

For the dyeing process, we used an infrared close bath sample dyeing machine. We followed the above-mentioned dyeing curve.

- At first, we set the dyeing parameter in the dyeing sample dyeing machine.

- We set the dye bath with sample and other auxiliaries at room temperature without dyes, salt, and soda.

- After rising to 400 C, we added dye solution and Salt (1st dosing)

- Now, raise the temperature to 90-950 C. Then, add soda ash, and salt (2nd dosing).

- Run the dye bath for 40-60 min at dyeing temperature 95-1000 C.

- After 40-60 min, cool down the dye bath temperature at 600 C and drop the liquor.

- Now, carried out after treatment process.

After treatment process:

Our dyeing pH was 10.5±0.5. So need to neutralize the alkalis. To neutralize the sample, we used acetic acid. We treated the dyed sample in acetic (1ml/L) solution for 5 minutes at room temperature. Then follow the recipe below for the aftertreatment process.

| Chemical | Amount (gm/l) |

| Detergent | 1.0-2.0 gm/l |

| Soda ash | 0.5-1.5 gm/l |

| Temperature | 95-1000 C |

| Time | 15 min |

| M:L | With enough water. |

- At first, rinse the sample with hot water for hot water for 10 min to remove unfix dyestuff.

- Now neutralize the sample by using acid at room temperature.

- Now soap wash is carried out according to the mentioned above recipe.

- Then, again rinse the sample with hot water.

- Finally, cold wash the dyed sample.

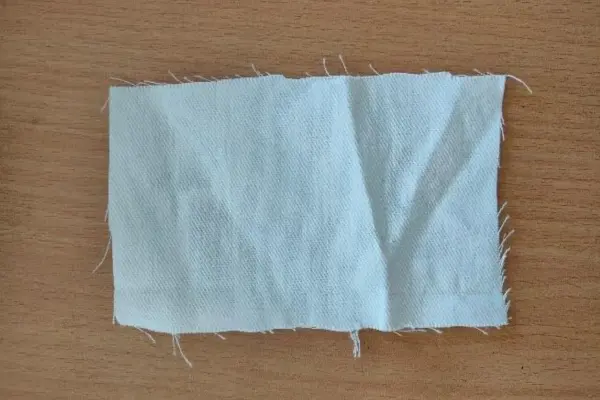

Final Result:

Precaution:

- We know, reactive hydrolysis when it is stored long time. So we should not store the dye solution.

- An inhalation of reactive dye dust can be dangerous. So we should use protective masks and safety glasses.

- Recipe calculation should be done carefully.

Conclusion:

Reactive dye is a popular dyestuff due the its excellent colorfastness properties. In this article, we described the reactive dye recipe with recipe calculaton. All information and dyeing procedure is collected from the textile dyeing factory. So, don’t forget to share my article with your social media and your friends. If you have any questions about this article, let us know by comment box.

References

- Hossain, M. F. (2015). Practice of Textile Coloration, Volume-I. Dhaka: Books Fair Publications.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhaka: Books Fair Publications.

- Kabir, D. S. (2016). Chemistry of Dyes & Pigments. Dhaka: Books Fair Publications.